Highly effective

products

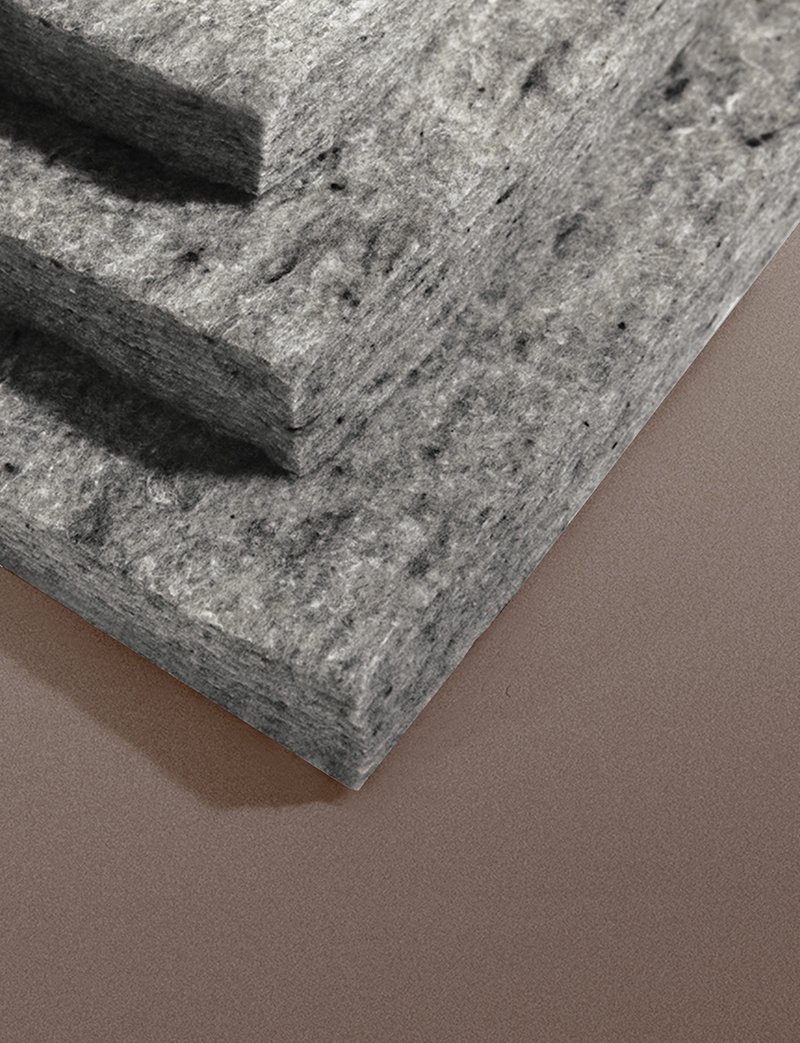

Wool has an unusual structure, which resembles overlapping scales like tiles. These physical properties allow wool to retain air within its fibres and to slow down its movement. Air that is captured in this way acts as insulation and protects the body from the external environment.

Another feature of wool is its hygroscopic nature: wool produces heat when it absorbs moisture (up to one third of its weight!) and releases it into the air. This explains why wool clothes retain their heat when humidity changes. It also explains why wool stays cool in hot weather.

It is clear, then, why sheep fare as well in the plains of Siberia as they do in the deserts of Australia.

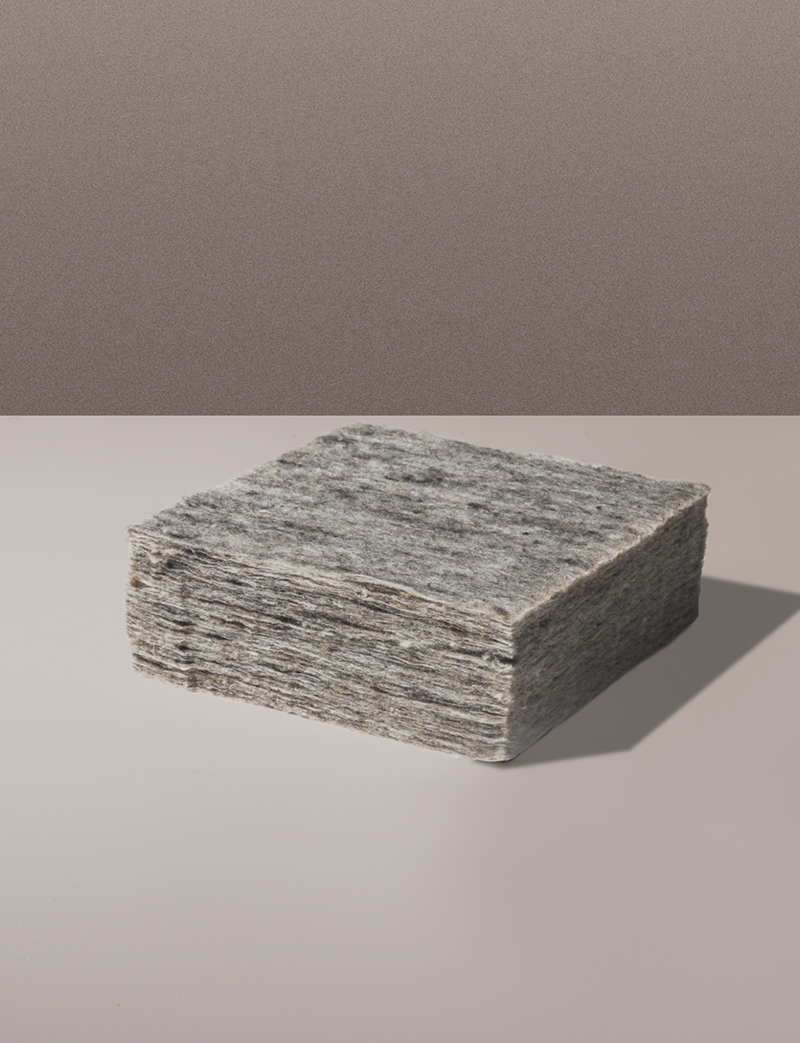

THERMAL AND SOUND PERFORMANCE – This raw material is sustainably collected by Belgian farmers and transformed by Woolconcept® into panels, felt or loose wool, which offer exceptional results in indoor environments, in particular in terms of calming acoustics, comfortable temperatures and stable air humidity. Sheep’s wool is a good thermal insulator, with a thermal conductivity co-efficient between 0.035 and 0.041 W/m.K. It is also effective for sound insulation purposes, in particular for airborne sound.

SHEEP’S WOOL PURIFIES THE AIR – A study conducted by Gabrielle Wortmann from the DWI (the German Institute for Wool Research) on ‘the absorption and fixing of pollutants in the air, such as formaldehyde, by wool’ shows that sheep’s wool is a sustainable solution for the absorption of formaldehydes and VOCs (Volatile Organic Compounds).

Key performance

A NATURAL MATERIAL – The properties of sheep’s wool make it the only natural insulator that retains and protects against heat, cold and humidity, all by filtering the air. Sheep’s wool has been put to the test over thousands of years. It is the only insulator whose aptitude has been continuously tested under the most extreme climatic conditions. It offers the best insulating properties* and a unique combination of advantages that no other insulating material can match.

1

* Thermal conductivity of 0.035 to 0.041W/m2K

This raw material is sustainably collected by Belgian farmers

and transformed in Belgium

A NATURAL FILTER (VOC) – The secret lies in keratin, the building block of the proteins that make up sheep’s wool. The molecules in the side branches of the amino acid are able to assimilate and neutralise harmful substances, such as formaldehyde. This results in a chemical reaction in which the pollutants are bound to these molecules or transformed. View the study here →

2

3

REGULATES HUMIDITY – Sheep's wool can absorb up to 33% of its weight in moisture without losing its insulating properties. This is why the vapour barrier is often unnecessary. It retains its thickness, without having a negative impact on the structure of the building. This is due to the unique structure of the protein fibre: it is water-resistant and, as a result, hydrophobic. This property is very beneficial for critical installations, for example, when there is a high level of condensation. Sheep’s wool also boasts another advantage: as a protein fibre, it is a hostile breeding ground for mould.

Our loose wool comes to us directly after it is processed

by TRAITEX in Verviers.

4

NOISE ABSORPTION – Sheep’s wool has very good sound-absorption properties, for a wide range of situations that require high-level performance. Equip ceilings with acoustic padding, or simply use sheep’s wool felt, to conduct important interviews in peace and quiet. Woolconcept® acoustic products are increasingly popular among contemporary architects, building engineers and construction foremen for schools, office buildings, conference rooms and private homes as sound insulation inside installation gaps and suspended ceilings – and for good reason too.

Electricity in the air? Never with wool! This natural material does not produce static electricity, which promotes a more regular heart rate and a quieter night’s sleep.

A natural rodent repellent.

FLAME RESISTANT – The natural fibre of sheep’s wool has an auto-ignition temperature of between 560 and 600°C. This is around two times higher than wood (270°C). Thanks to their special manufacturing process, sheep’s wool products from Woolconcept® do not require any additional flame-retardant products and achieved exceptional results during standardised European tests concerning their reaction to fire.

5

LOW EMISSIONS – One of the advantages of sheep’s wool is that it is a naturally effective, healthy insulator with a very small impact on the environment. Furthermore, sheep’s wool is produced locally and does not require significant transport. The embodied energy consumed by sheep’s wool is 55 kWh/m³, from extraction to recycling, including its transformation.

6

Wool traps approximately 80% of air in its volume.

Wool can be stretched and returns to its original

shape relatively easily.

7

REPELS RODENTS – Yes, contrary to popular opinion, wool has the ability to shrink, which prevents rodents from settling inside. Rodents do not digest sheep fibres. Moreover, it will also be impossible for them to burrow caverns in our semi-rigid panels.

8

AFFORDABLE – The ability of wool to regulate humidity, prevent mould and repel rodents makes our insulation products sustainable and resistant over time. It is clear that these properties fully justify potentially paying more compared to other conventional or non-conventional insulating materials, which are less tolerant to these kinds of issues and, as a result, likely to be replaced more quickly. Buying from Woolconcept means investing in the long term and saving.

It can absorb up to 33% of its weight in moisture.

Hair is made up of keratin, a fibrous protein with a high level of cysteine (approximately 12%). These are the disulphide bridges of cysteine, which lend consistency to the keratin. They are resistant to water, acids, bases and most enzymes.

Installation

The stability of wool fibres and their high density make our products extremely stable and quick and easy to install.

FYI: sheep’s wool fibres only break after being bent more than 20,000 times.

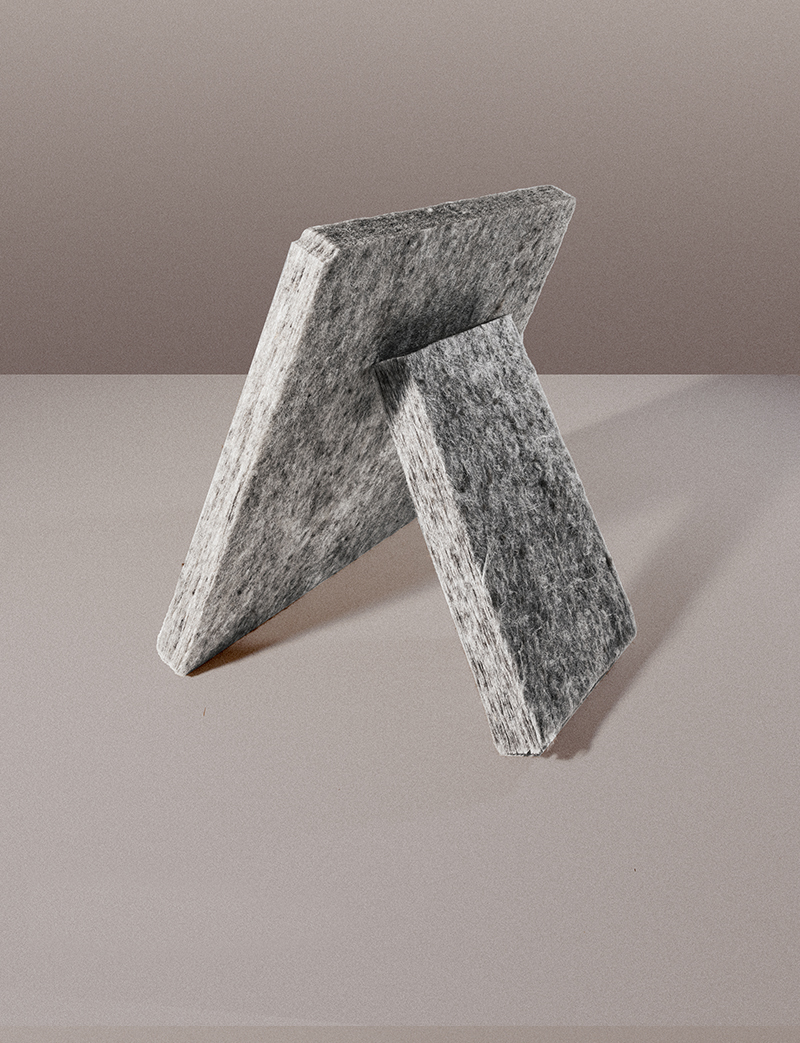

For BELGOLAN (semi-rigid panel), the unit can be fixed (wedged) instead of being nailed/stapled. Simply cut the panel based on the width of the structure in place, while keeping a surplus of two centimetres to ensure a spring effect. The structure can be made of metal or wood. Based on our experience with installations, Belgolan allows for an increase of 17% in speed compared to other flexible insulation.

For SOFTLAN, simply ventilate the fibres by removing them from the bundle and placing them on the surface that needs to be insulated. No additional tools are needed. It couldn’t be simpler.

For SONOLAN-LINE: place the strips on the surface and cut them to size.

For TERRALAN: place the strips on the surface to be covered, with a ten-centimetre overlap between each strip, make holes if there are studs and staple every metre on the edge of the felt to keep it in place correctly.

Downloads

Technical sheets

Installation instructions

Certifications

Images

Follow us

© Woolconcept. All Rights Reserved.

Downloads

Technical sheets

Installation instructions

Certifications

Images

Follow us

© Woolconcept. All Rights Reserved.